A superior non-combustible construction board material with wide-ranging application for all types of commercial and residential projects. Usable for both indoor and outdoor purposes, it provides a hard, long lasting surface with the look and feel of cement plastering. As an improved alternative to gypsum drywall or cement board, it is fireproof and resistant to damage from water, humidity, freezing, termites, chlorine, salt and more.

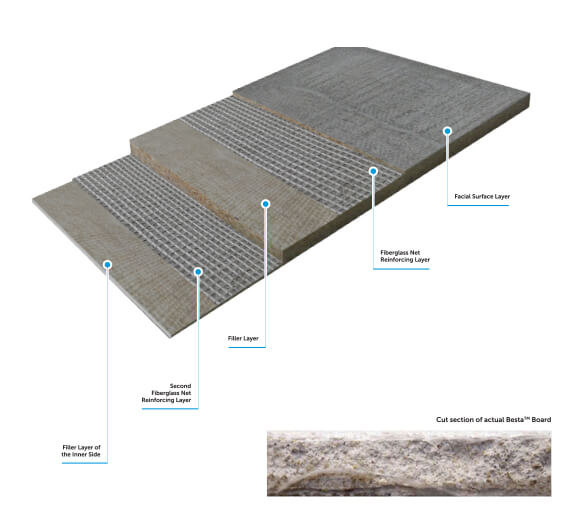

Developed through years of field-tested research and continuous innovation, the Besta™ Board undergoes strict quality control during production to create a proprietary magnesium oxide board that is superior to typical options in the market. It comprises natural silicate, Magnesium Oxide, Magnesium Chloride, fiber glass mesh and special additives created by Well&Able.

A superior non-combustible construction board material with wide-ranging application for all types of commercial and residential projects. Usable for both indoor and outdoor purposes, it provides a hard, long lasting surface with the look and feel of cement plastering. As an improved alternative to gypsum drywall or cement board, it is fireproof and resistant to damage from water, humidity, freezing, termites, chlorine, salt and more.

Developed through years of field-tested research and continuous innovation, the Besta™ Board undergoes strict quality control during production to create a proprietary magnesium oxide board that is superior to typical options in the market. It comprises natural silicate, Magnesium Oxide, Magnesium Chloride, fiber glass mesh and special additives created by Well&Able.

Fire Resistant

Water Resistant

Impact Resistant

Mold Resistant

Termite Resistant

Sound Insulation

Thermal Insulation

Freeze Thaw Resistance

Non-Toxic

Easy to Install

Magnesium Oxide (MgO)

Magnesium Chloride (MgCl2)

Natural Silicate (SiO4)

Fiber Glass Mesh

Additives

Roof, Ceiling, Floor, Fencing

External Wall

Internal/Partition Wall

(Dry & Wet Areas),

Column, Beam, Window,

Door Frame

| Units | Length | Width | Thickness Range | |

| Basic Dimensions | mm |

2400/2700/3050/3600 |

1200/1220 | 6-24 |

| Density Kg/m3 Nominal | 950 to 1200 kg/M3 |

| Tensile Strength Mpa Minimum | 5Mpa |

| Bending Strength Mpa Minimum | 9Mpa-16Mpa |

| Thinkness Tolerance Ln m m | ±0.5 |

| Specific Absorption Ratio Maximum in % | 22% |

| Moisture Distortion Rate Maximum in % | 0.34% |

| Sustained Combustion Time in % | 0% |

| Length Tolerance in mm | ±4 |

| Shock Strength KJ/m2 Minimum | 5.5KJ/M2 |

| Thermal Conductivity W/m K Maximum | 0.132W/mk |

| No Asbestos Content | |

| Flatness in m m | 2mm |

| Temperature Shrinkage Rate in % Maximum | 0.1% |

| Fire Redundancy (Non-Combustible A Grade) | A Grade |

| Minimum Bending strength Mpa | 10.5Mpa |

| S/N | Type of Test | Clause,Methods | Besta Mgo Board(10mm thick) | Besta Mgo Board(16mm thick) |

| 1 | Density | Cl.6.3,ISO TR 1896 | 1060kg/m3 | 1030kg/m3 |

| 2 | Bending Strength (Dry and Saturated) | Cl.6.4,ISO TR 1896 | 5.5N/mm2(Dry);6.0N/mm2(Saturated) | 10.1N/mm2(Dry);9.5N/mm2(Saturated) |

| 3 | Linear Thermal Shrinkage | Cl.6.7,ISO TR 1896 | Samples softened &crumpled after subjected to 950℃ for 4hrs | Max.shinkage:-2.2%; Max.expansion:+2.3% after subjected to 950℃ for 4 hrs |

| 4 | Moisture Movement | Cl.8,ASTM C 1185 | 0.08% | 0.21% |

| 5 | Water Absorption | Cl.9,ASTM C 1185 | 22.00% | 21.60% |

| 6 | Moisture Content | Cl.10,ASTM C 1185 | 9.60% | 7.50% |

| 7 | Water Tightness | Cl.11,ASTM C 1185 | Dampness appeard after 5 hours | Withstand 50mm water head without sign of dampness at bottom suface after 24 hours |

| 8 | Non-Combustibiltiy | BS 476:Part4 | Non-combustible material | N.A |

| 9 | Thermal Conductivity | ASTM C518 | 0.132 W/m k (300*300*10mm) | N.A |

| 10 | Thermal Conductivity | ASTM C518 | 0.133 W/m k (300*300*100mm sandwich panel) | |

| 11 | Thermal Conductivity | ASTM C518 | 0.196 W/m k (600*600*128mm sandwich panel) | |

(Netional Research Center of Testing Techniques for Building Materials)

|

BESTA Board

|

Calcium Silicate Board

|

Cement Board

|

BESTA Board Advantages

|

|

|

Basic Compounds Used

|

Natural Silicates, (MgO), (CaCo3), Wood Fiber or Glass Fiber

|

Wood chips, refined sand, cement, cellulose, Additives

|

Portland/Cement aggregate, water, additives, chemicals

|

Lightweight, non- flammable, natural minerals, inert & non-contaminating

|

|

Density

|

1100 kg/m3

|

1300 kg/m3

|

2700 kg/m3

|

Lighter weight for comparable strength, stronger & more rigid

|

|

Surface & Color

|

Uniform Smooth & consistent, Chalk white, sandy peach, slate grey

|

Off-whitish

|

Grayish

|

Selection of colors, smoother surface for receiving paint or left natural.

|

|

Thermal Conductivity

|

0.216 W/mK

|

0.35 W/mK

|

0.22 W/mK

|

More energy efficient

|

|

Bending Strength

|

15 N/mm2

|

Dry 29 N/mm2

Wet 17N/mm2

|

12N/mm2

|

Stronger & more flexible

|

|

Modulus of Elasticity

|

6045 N/mm2

|

6000 N/mm2

|

5500N/mm2

|

More rigid

|

|

Stability of thickness, swelling after 24hours in water

|

0.2% (Maximum even after 7 days)

|

0.78%

|

1.8% Cement Board – Malaysia

0.7% VirocBrad – Portugal

|

Moisture resistant, lower swelling rate, won’t degrade in water over time.

|

|

Dry Shrinkage (heating & cooling when dry)

|

<0.08%

|

<0.09%

|

0.17%

|

Greater dimensional stability, resistance to cracking

|

|

Surface Alkalinity

|

PH between 10-12

|

PH 13

|

Ph 11-13

|

Relatively lower alkalinity

|

|

Moisture Content

|

10%

|

10%

|

12%

|

Relatively lower moisture content

|

|

Fire Resistance & Combustibility

|

Rated Class 1 through fire resistance Test (Non-Combustible)

|

Not Available

Not Rated

|

Not Available

Not Rated

|

Non- combustible, highly fire resistant, tested for fire rating to 1 hour with 12mm boards

|

|

Sound Attenuation

|

42 dB reduction with 10mm board both sides & 80mm mineral Rock infill, Total thickness is 100mm

|

Varies with brand, equal or lower depending on thickness

|

Significant Lower Performance

|

dB reduction increases using thicker wool & board

|

Besta Board ASTM E90-4 Airborne sound transmission Loss test report.jpg)

Besta Board ISO 140-3 Airborne Insulation test report.jpg)

Besta Board ISO 140-6 Impact Sound Insulation test report.jpg)

Besta Board ISO TR 1896, ASTM C1185 16mm Physical & Mechnical test report.jpg)

Besta Board ISO TR 1896,ASTM C1185 10mm Physical & Mechnical test report.jpg)

Besta board BS476-4 Non-Combustibility test report copy.jpg)

SETSCO Product Certification Scheme-75mm Dry Wall copy 2.jpg)