Besta™ ALC (Autoclaved Lightweight Concrete) Panel is a sustainable green building material for simple and effective construction. These panels are made of cement, lime, gypsum and aluminum additives that help create bubbles within, hence making the panel lighter and thermal efficient.

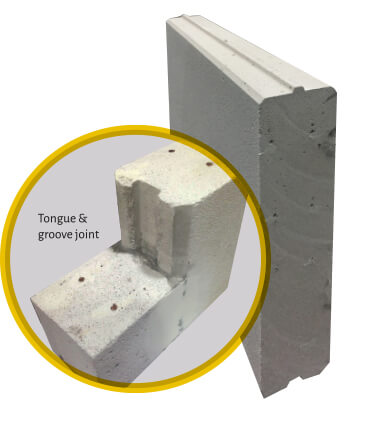

The tongue and groove of these panels makes the joint more secure and tight in terms of water leakage and with its lightness in weight, makes the installation easier and faster.

Besta™ ALC Panels are produced with precision, only allowing for a 1.0 mm tolerance for length, height and width. This level of precision makes it possible to avoid cracking by way of coating thin mortar and putty.

Installation is a dry and continuous process, and not as restrictive as that of masonry or bricks, thus enhancing the speed of construction. Using a special adhesive on the joints allows dry surface panels to achieve adhesion. ALC surface can be directly coated with plastering putty/skim coating and ready to achieve painting finishes.

Besta™ ALC Panels constitute inorganic and non-combustible materials, and is an ideal Class A fireproof construction material. A 100mm thick wall can resist fire for as long as 4 hours. With the presence of bubbles in the panel, thermal conductivity is high and heat is migrated slowly. In the event of fire incident, ALC panels will not release any smoke or toxic gas. Even a 50mm panel can effectively resist and prevent the spread of fire, and protect the structure from the impact of the fire. Compared to traditional forms of build, it is a safer, more economical and reliable system for energy conservation and heat insulation.

Fire Resistant

Water Resistant

Impact Resistant

Mold Resistant

Termite Resistant

Freeze Thaw Resistant

Better Sound Insulation

Enhanced Thermal Insulation

Non-Toxic

Easy to Install

Manpower Saving

Ease of Handling

Cement

Lime

Gypsum

Aluminium

Additives

External Wall,

Fire Wall (up to 4 hrs)

Internal/Partition Wall,

Floor, Roof, Fencing,

Column Wrapping

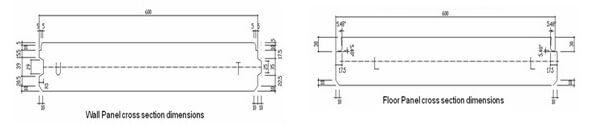

The autoclaved aerated Lightweight concrete panel comes in typical size of 100mm thick x 600mm wide, with various lengths used for outside wall, inner wall, floor and roof. Table below shows typical panel dimensions.

| Panel | Width (mm) | Length (mm) |

| Wall Panel 100mm thick | 600 | 2700; 2850; 3000; & custom length |

| Floor Panel 100mm thick | 600 | 2000; 2200; & custom length |

| NO. | Product | Specification(mm) | Requirement | |||

| L | B | H | ||||

| 1 | External wall panel | ≦ | 6000 | 600 | 200 | Groove |

| 2 | ≦ | 6000 | 600 | 175 | ||

| 3 | ≦ | 5750 | 600 | 150 | ||

| 4 | ≦ | 4690 | 600 | 125 | ||

| 5 | ≦ | 3750 | 600 | 100 | ||

| 6 | ≦ | 6000 | 600 | 100-200 | ||

| 7 | Internal wall panel | ≦ | 6000 | 600 | 150 | |

| 8 | ≦ | 5050 | 600 | 125 | ||

| 9 | ≦ | 4250 | 600 | 100 | ||

| 10 | ≦ | 3000 | 600 | 75 | ||

Remark:Minimum Length 600mm ,unite change 10mm

AS1534-4 ALC Fire Resistance test.jpg)

ISO 140-3 ALC airbourne sound test.png)

ISO 140-6 ALC Impact sound test.png)

SS492 ALC performance test.png)